Our engineers have being successfully exploiting the sidetracking technology in abandoned wells by means of casing’s window milling in production casing sizes from 5” to 6-5/8” and sidetracking from there with either directional or horizontal hole and its further casing and cementing. It is included the following steps:

Our engineers have being successfully exploiting the sidetracking technology in abandoned wells by means of casing’s window milling in production casing sizes from 5” to 6-5/8” and sidetracking from there with either directional or horizontal hole and its further casing and cementing. It is included the following steps:

Isolating the production casing from below the place of proposed sidetrack;

Isolating the production casing from below the place of proposed sidetrack;- Casing window or section milling;

- Oriented side tracking;

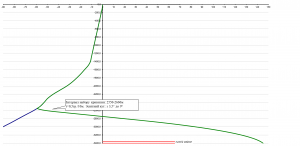

- Drilling of directional or horizontal section with required horizontal displacement from the old hole;

- Running liners of 2-7/8” – to 4-1/2” and its cementing;

- Flow intake.

Sidetracking in abandoned/suspended wells with horizontal or subhorizontal sections

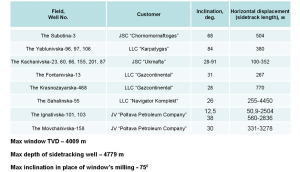

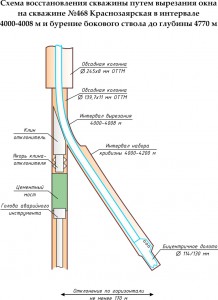

Firstly in CIS on the depth of over 4000 м in 5-1/2” casing the window was milled and sidetrack section was drilled to depth 4770 м. 4” liner was successfully ran and cemented.

Firstly in CIS on the depth of over 4000 м in 5-1/2” casing the window was milled and sidetrack section was drilled to depth 4770 м. 4” liner was successfully ran and cemented.

The following wells were successfully sidetracked with horizontal or directional sections from 5-1/2”, 5-3/4”, 6-5/8” 9-5/8” casings:

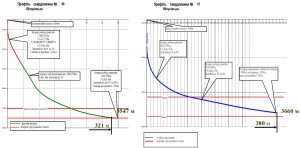

- the Yablunivska-96, 97 (2013)

- the Кrasnozayarska-468 (2013)

- the Fontanivska-13 (2012)

- the Nothern-Dolyna-185 (2001)

- the Каchanivska-155,23,201,60,66 (2000-2005)

For Karpatygaz LLC we had sidetracked the Yablunivska-96 and 97 wells with horizontal sections in 2013:

Sidetracking from abandoned/suspended wells

First in CIS on the Fontanivske field the window was milled and the sidetrack was performed from the 5-1/2” casing under HPHT conditions with mud weight 1.85 gr/sm3.